Bridge in HafenCity, Hamburg

Gottlieb Paludan Architects has created a design proposal for a new bridge over Moldauhafen in Hamburg, in collaboration with Hardesty & Hanover and Werner Sobek. The bridge will facilitate traffic options for pedestrians, cyclists and buses in HafenCity's Grasbrook neighborhood.

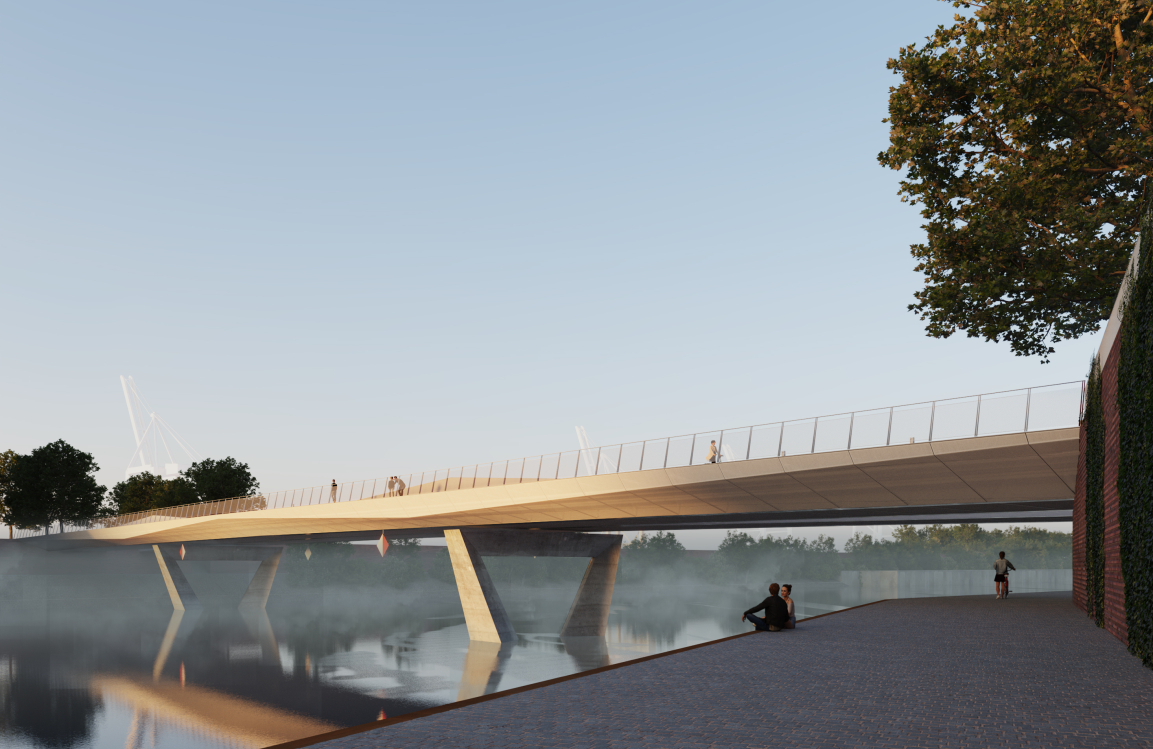

The HafenCity development area is expanding south of the Elbe River, in the Grasbrook area. The Grasbrook area was until recently characterized by buildings related to port operations, but these have now been demolished to make way for residential areas. Moldauer Hafen is the northernmost harbor basin on Grasbrook and the competition brief was to develop a proposal for a combined pedestrian, bicycle and bus bridge that would connect the 2 quay sides of the harbor basin in a north-south axis. The expanded traffic options over the bridge is an important element in the promotion of the new district and the intention is to make waterfront living in Hamburg more accessible and sustainable.

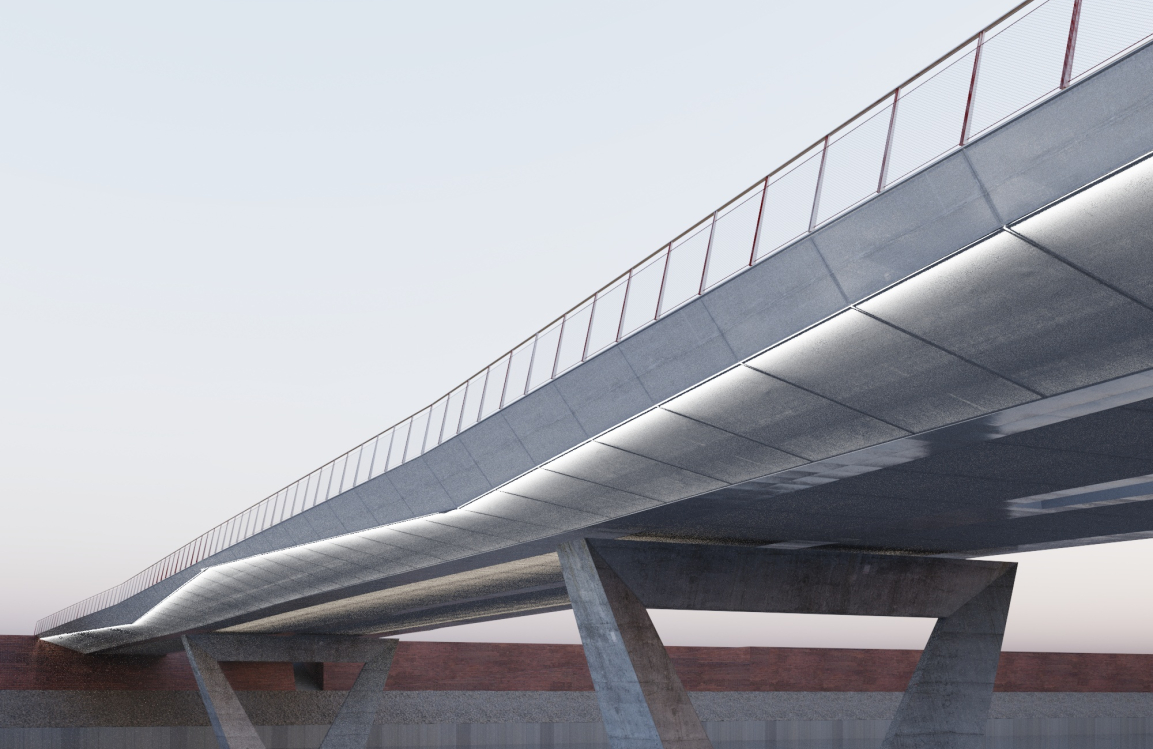

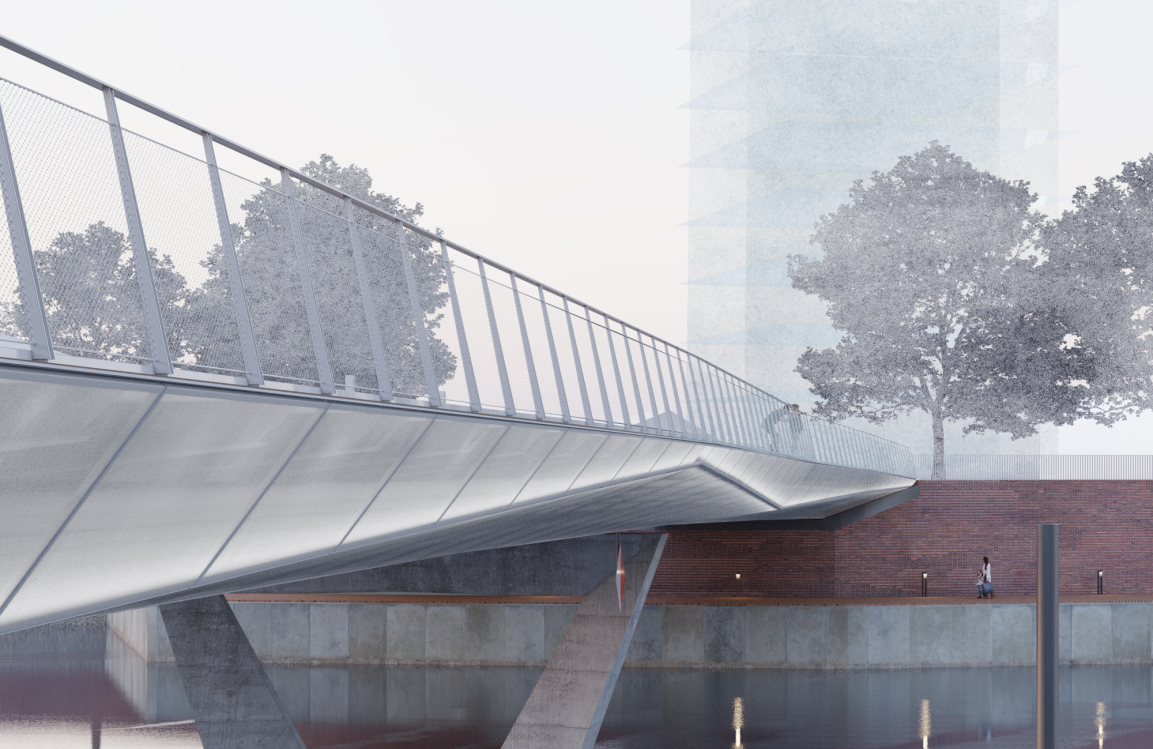

The aim of Gottlieb Paludan's design proposal is to create infrastructure that fits into the existing family of bridges in Hafencity in Hamburg. A bridge design with a slim longitudinal profile and structure that can function as part of an active public space while meeting all functional requirements. The cross-section of the bridge at the quayside is divided into three parts - pedestrians and cyclists are separated from bus traffic in the middle. In the middle of the bridge, these 3 strands are joined together. Here it will be possible to create a space situation for special occasions - e.g. the Hamburg Marathon. Hamburg Marathon. The bridge is a highly optimized structure and the design proposal incorporates materials such as wood and membranes to save weight.

The promenade under the bridge is visible from the bridge deck and safety is increased through the visual overview. The view of Hamburg, the use of local materials, path and connection systems, the park and the museum ships of the German Harbor Museum have been the main sources of inspiration for the design, which is rooted in tradition while pointing towards a sustainable future.

Sustainability has been an essential design basis for the design proposal and is reflected in all structural features. This is reflected in the choice of superstructure spans, the efficient design of the superstructure cross-section and precise structural analysis, which together make it possible to achieve a very low material consumption of only 390 kg of structural steel per m² of bridge area for the superstructure. In addition, prefabricated steel and reinforced concrete components will save both costs and construction time by avoiding costly temporary structures.

Careful selection of materials and optimization of the load-bearing elements actively minimizes CO2 emissions and conserves resources. For example, using recycled structural steel remelted in an electric arc furnace. This results in a total saving of 950 t CO2-eq. in life cycle phases A1-A3. By using CEM III/B cement in concrete production for abutments and bridge piers, 230 t CO2 can be saved compared to the average for concrete structures of the same scale. The 1,180 t of CO2 saved is equivalent to the amount that 92,400 trees would absorb over the course of a year.